Sparing, VFF

Spares for VFF Rotary Piston Flowmeters

Provide a serial or project number, and we can quickly identify the correct spares code for any VFF meter. In many cases, a simple tag number is sufficient. Our records cover a wide range of sizes, from LF03, LF05, LF15, and MF30 to VFF4, VFF8, HF20, and larger models. We can trace both current and legacy designs — including rare or discontinued units — that may seem impossible to replace.

An original calibration certificate is especially useful, as it confirms the flow range, meter performance, and often provides valuable clues to the mechanical and electrical components used. Many meters will have had replacement rotors or pressure‑balanced chambers fitted during their service life, and this information helps ensure the right parts are supplied first time.

Positive Measurement can provide sensors that replace or improve on the original. Sensor selection is relatively simple, and we can help confirm the type and setup instructions.

Replacement parts for VFFs

The VFF’s modular design brings a key advantage — upgradeability.

Meters can be adapted throughout their service life with changes to flow range, accuracy enhancements, or alternative body materials. Instrumentation can also be swapped to alter the Hazardous Area certification, for example converting from Ex i to Ex d or vice versa — a major benefit when repurposing equipment for a new application.

As process conditions evolve, the pressure‑balanced chamber (PBC) can be recalibrated or replaced to extend the lifespan of the meter, its instrumentation, and its cabling. PBCs can be returned for refurbishment or calibration, or supplied as complete replacements, often with a new rotor and sensor to maintain peak performance.

Sensors for Rotary Pistons

Typical Spares Codes

Did you know there have been five generations of sensors used on Rotary Piston meters?

Early designs evolved through several iterations before reaching the current specification, each bringing improvements in accuracy, reliability, and ease of installation. From the first reed-based systems to the modern CIFM sensors (shown above) supplied since 2015, this progression reflects decades of refinement to meet changing industry demands.

(CIFM is the acronym for Chemical injection Flow Meter)

- RC covers serial numbers VFF101 to VFF437

- RH VFF335 to VFF396

- RL VFF212 to VFF892

- M6 VFF911 to VFF4594 et al

- CIFM from VFF4593 to the present day

RC sensors were mounted in either a PVC or stainless steel cylinder, with a typical spares code containing “RC.” The calibration certificate specified the number of active and spare reeds, and “RC” would also appear in the stock code or product description.

RH and RL sensors were similar in design, using a PCB to select which reed(s) were active. They incorporated a mechanism to fine‑tune the sensor for an even mark‑space ratio, for example: REEDHLIFT40X.

M6 sensors almost always used a single sensing element, with a typical spares stock code such as SENSORLF5‑10GX.

With the arrival of the CIFM system, the sensor was housed in either a plastic or stainless steel enclosure, with one or two active elements. Two‑element versions were used when reverse‑flow detection was required. Only two lengths were produced, generally corresponding to the VFF’s pressure rating. Common part numbers include CIFM‑2RSSENSORX and CIFM‑2RSSENSORLARGEX.

For all sensor types, providing the meter’s serial number is the fastest way to identify exactly what you have.

Spare rotors:

Rotary piston rotors are available in a variety of sizes/flow ranges and a variety of materials. Wider and/or non-standard flow ranges might change the construction or the calibration.

Call us for advice on swapping rotors or pressure-balanced chambers.

Typical codes: VFFROTMF30FC2.5, CIFM-VFFROTLF03TIPVD

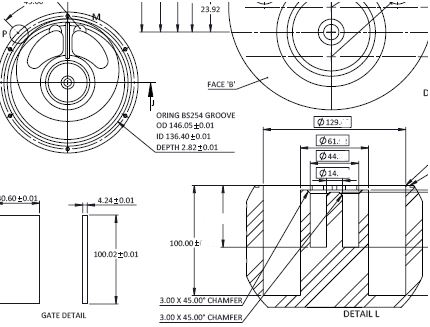

Spare chambers:

Rotary piston pressure-balanced chambers are available in various sizes/flow ranges and various materials. Wider and/or non-standard flow ranges might change the construction or the calibration.

Call us for advice on swapping rotors or pressure-balanced chambers.

Typical codes would include the three characters: PBC, e.g. VFF4PBCXCARBROTHAST, CIFM-LF03PBCPVDPX

Need Help With VFF Spares? We Are The Experts!

Talk to us

Have any questions? We are always open to talk about your business, new projects, creative opportunities and how we can help you.