Projects

Project One

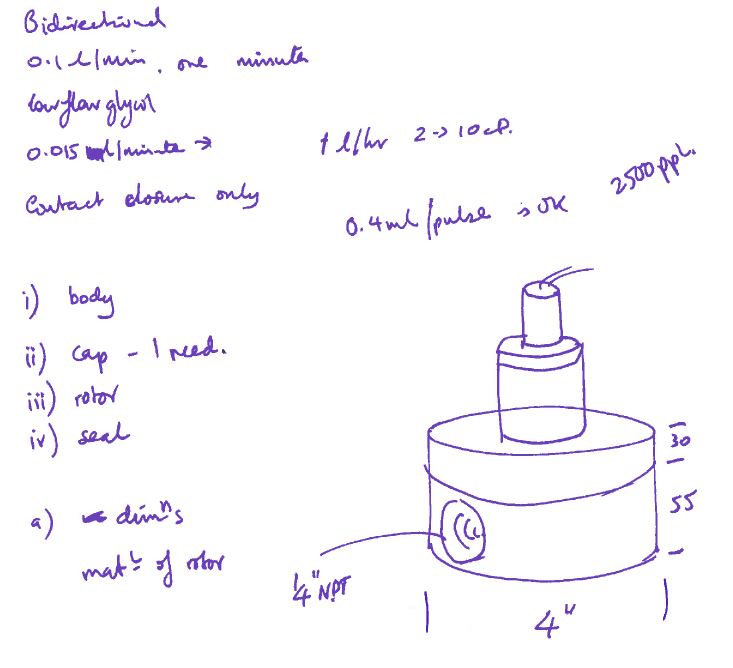

In the early 1990s, 112 compact hydraulic flowmeters were supplied for valve positioning and leak detection on a North Sea platform operating at 520 bar. Using HW540 hydraulic fluid, the system handled low‑viscosity media, high turndown, and tight accuracy requirements across summer and winter conditions. Meters were calibrated for bidirectional flow with high‑resolution pulse outputs for precise valve stroke monitoring. With a turndown of around 300:1 and kickoff flow under 10 ml/min, they provided reliable operation and rapid leak detection during infrequent valve movements.

Project Two

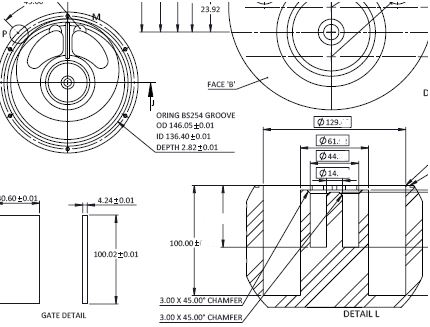

When a deepwater project required flow measurement at 20 gallons per minute and 17,000 psi, options were extremely limited. For Chevron’s ultrahigh‑pressure Anchor development in the Gulf of Mexico, Charles engineered a precisely sized device optimised for both flow rate and extreme pressure. Designed for subsea methanol pump duties, it met the demanding requirements of one of the world’s first 20,000 psi offshore projects. This bespoke solution ensured reliable performance in a high‑stakes environment where accuracy, durability, and operational integrity are critical.

Project Three

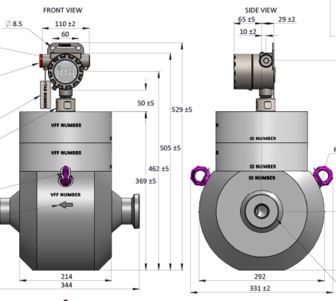

When the requirement called for combining 400 litres per minute with 6″ ANSI 2500 flanges in a positive displacement meter, engineering innovation stepped up. Built on VFF rotary piston technology, this custom meter handled lean MEG at over 260 bar with precision and durability. Scaling VFF design to 6″ connections was a significant challenge, but the result delivered high‑capacity, high‑pressure measurement without compromising accuracy — proving that VFF technology performs just as well when flow rates climb as when pressures soar.

Project Four

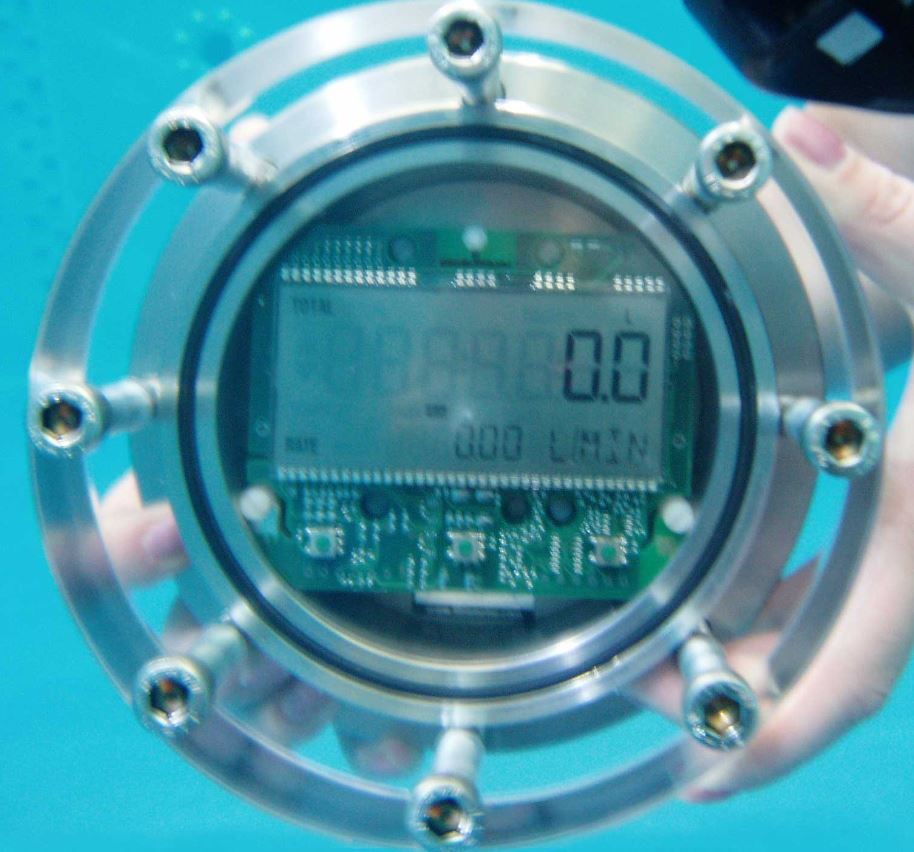

Faced with the need for an ROV-readable subsea flowmeter with no external power and a wide flow range, a tailored solution was delivered for Subsea 7 in 2005. Rated to 600m depth (60 bar), the meter featured a custom enclosure with off-the-shelf components and mechanical indicators designed for legibility at depth. Operating without power, it provided clear visual readouts for both flow rate and totals, even when submerged in hydraulic oil (Mobil DTE22, 21cSt at 40°C). This ensured reliable performance and easy monitoring by ROV, meeting demanding installation requirements offshore.

Project Five

Faced with the daunting brief—Super Duplex construction, Grayloc hubs, ultra-wide and ultra-low flow ranges, and 1,035 bar pressure—Charles engineered a bespoke inline device with US-approved Exd flameproof housing. The resulting flowmeter series features five customizable options, from special connections to advanced communication outputs like HART, with only core parts standardized. With 179 units delivered, it stands as the largest project order for Litre Meter, supporting Chevron’s landmark deepwater operation in the Gulf of Mexico.

Project Six

The requirement was clear — deliver over 100 litres per minute while using exceptionally high‑grade Duplex stainless steel and custom hubs for installation in the Norwegian North Sea. Drawing on proven VFF rotary piston technology, a customised positive displacement meter was built to handle MEG injection at high pressures, preventing hydrate formation in deepwater wells. Combining specific materials, hubbed connections, and robust engineering, it offers dependable chemical dosing performance under extreme offshore pressure and temperature conditions.

- “Understanding Flowmeter Technologies: A Comprehensive Overview“

- “Choosing the Right Flowmeter for Your Application: Factors to Consider”

- “Advancements in Flowmeter Design: From Traditional to Cutting-Edge”

- “Calibration and Accuracy in Flowmeters: Best Practices and Challenges”

- “Flowmeter Selection Guide: Matching Technology to Fluid and Industry”

- “Flow Measurement Techniques Demystified: A Comparative Study”

- “Optimizing Process Efficiency with Flowmeters: Case Studies and Insights”

- “The Role of Flowmeters in Energy Conservation and Environmental Sustainability”

- “Troubleshooting Flowmeter Issues: Common Problems and Solutions”

- “Future Trends in Flowmeter Innovation: IoT Integration, Smart Sensors, and Beyond”

Talk to us

Have any questions? We are always open to talk about your business, new projects, creative opportunities and how we can help you.