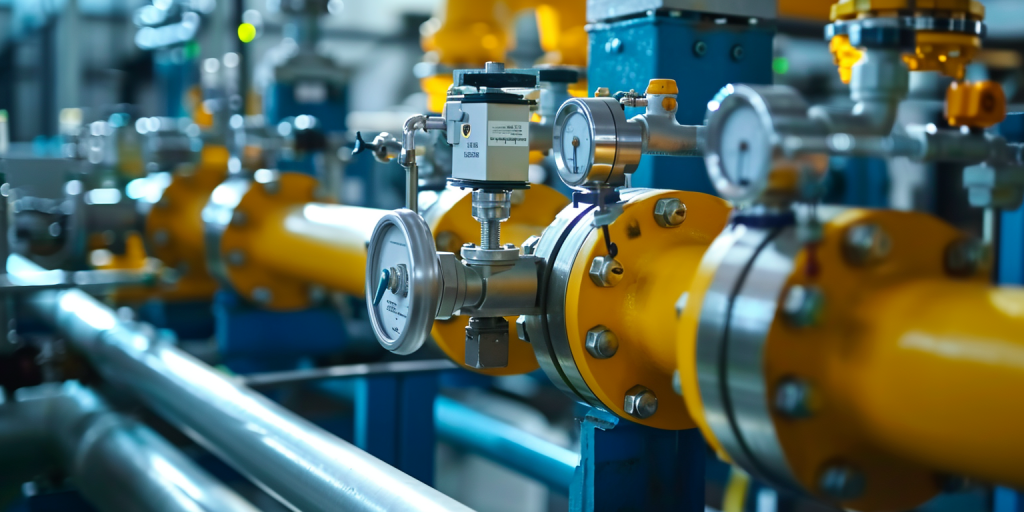

Flow measurement is a fundamental process in various industries, essential for process control, quality assurance, and resource management. With a multitude of flow measurement techniques available, understanding the advantages, limitations, and applications of each is crucial for making informed choices. In this comparative study, we demystify different flow measurement techniques, shedding light on their principles and highlighting their relative strengths and weaknesses.

1. Differential Pressure (DP) Flowmeters:

- Principle: DP flowmeters create a pressure drop across a flow element (e.g., orifice plate) and measure the resulting pressure difference to calculate flow rate.

- Applications: Versatile, used in various industries for measuring gases, liquids, and steam.

- Pros: Widely available, cost-effective, suitable for high-pressure applications.

- Cons: Pressure loss, limited accuracy in low-flow conditions.

2. Electromagnetic Flowmeters:

- Principle: These meters utilize Faraday’s law of electromagnetic induction to measure the flow rate of conductive fluids.

- Applications: Ideal for clean liquids with high conductivity, such as water and wastewater.

- Pros: No moving parts, low pressure drop, accurate, resistant to corrosion.

- Cons: Limited use with non-conductive fluids, high-ish initial cost.

3. Ultrasonic Flowmeters:

- Principle: Ultrasonic flowmeters use sound waves to measure the velocity of fluid flow.

- Applications: Versatile and suitable for clean liquids and gases.

- Pros: Non-intrusive, no moving parts, accurate, suitable for various fluids.

- Cons: Higher initial cost, limited accuracy with highly turbulent flows.

4. Coriolis Mass Flowmeters:

- Principle: These meters rely on the Coriolis effect, where vibrating tubes deform as fluid flows through, measuring mass flow directly.

- Applications: Precise measurement for liquids and gases, especially in chemical and food processing.

- Pros: High accuracy, direct mass measurement, suitable for multiple fluid types.

- Cons: Higher cost, limited to low- to medium-flow rates and low to medium viscosities.

5. Thermal Mass Flowmeters:

- Principle: Thermal flowmeters measure the cooling effect of a fluid on a heated sensor.

- Applications: Accurate for gas flow measurement, including air, natural gas, and industrial gases. Some liquid applications.

- Pros: Low pressure drop, suitable for low-flow rates, wide turndown ratio.

- Cons: Limited to gases, sensitivity to changes in temperature and composition.

6. Vortex Shedding Flowmeters:

- Principle: Vortex meters measure the frequency of vortices created by an obstruction in the flowstream.

- Applications: Used for gas and liquid flow measurement in pipes.

- Pros: No moving parts, suitable for high temperatures and pressures.

- Cons: Limited accuracy in low-flow conditions, sensitivity to vibrations.

7. Positive Displacement Flowmeters:

- Principle: These meters trap and measure a fixed volume of fluid, making them suitable for viscous liquids.

- Applications: Ideal for measuring oils, chemicals, and pharmaceuticals.

- Pros: High accuracy, suitable for low-flow rates, versatile for various viscosities.

- Cons: Pressure drop, limited turndown ratio.

8. Turbine Flowmeters:

- Principle: Turbine meters use a spinning rotor to measure flow velocity.

- Applications: Common in the oil and gas industry for measuring hydrocarbons.

- Pros: High accuracy, suitable for high-flow rates, compact design.

- Cons: Limited for low-viscosity fluids, sensitivity to impurities.

Each flow measurement technique has its place in various industries and applications. Choosing the right method depends on factors like fluid type, flow range, accuracy requirements, and budget constraints. Understanding the principles and trade-offs of each technique is key to making informed decisions for effective flow measurement in diverse industrial processes. Ask the experts, contact us.